by Yogi Nelson

Welcome to the BlockchainAIForum

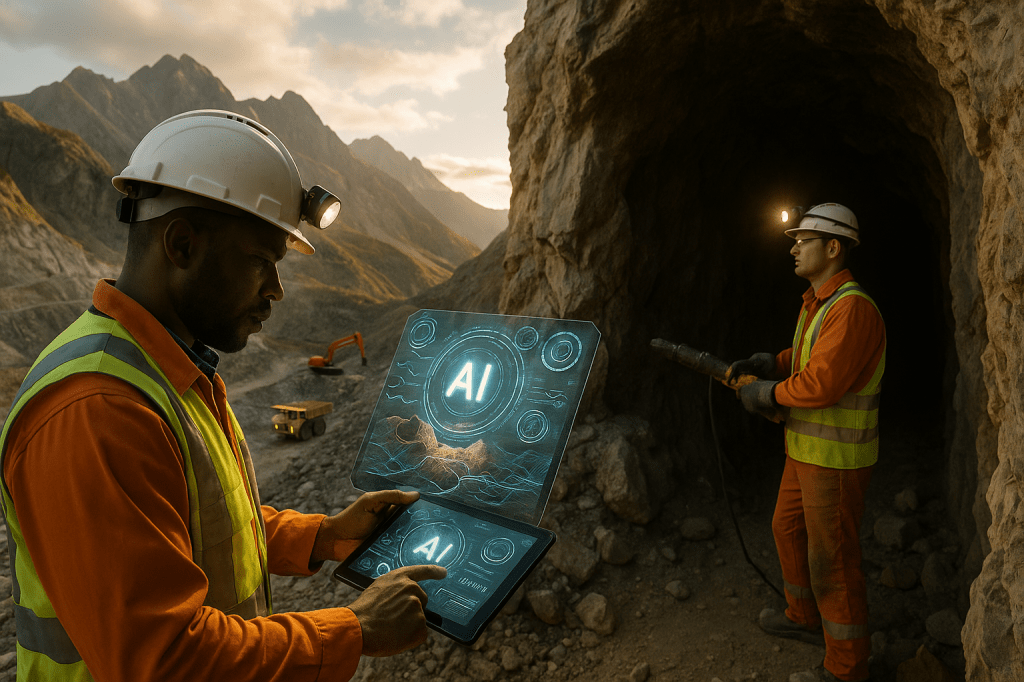

Discovery and extraction of precious metals—gold, silver, platinum, palladium—has relied heavily on manual geological interpretation, slow survey cycles, and trial-and-error drilling since about 1850. Making the “boring” process boring. lol. Today a new queen sits atop the golden throne of precious metals discovery and extraction! And she offers excitement—her name is artificial intelligence (AI)! Ms. AI is re-engineering the precious metals sector from the ground up—pun intended. lol!

Why has she ascended? For the simple, yet complex, reasons that as ore deposits become deeper, grades decline, and environmental expectations increase, AI offers solutions that improve efficiency, reduce costs, and minimize risk. Let’s “dig” into this phenomenon by “extracting” how AI is being deployed across the precious-metals value chain—from exploration and drilling to processing, sustainability, and blockchain-based supply-chain verification.

AI-Driven Exploration: Faster, Cheaper, and More Accurate

Predictive Geological Modeling

Machine-learning models analyze enormous geological datasets—satellite imagery, geochemical surveys, seismic readings, magnetic anomalies, and historical drilling logs. What’s the point of doing that? Answer—to identify high-probability mineralization zones! AI can detect “hidden patterns” in rock structure that human geologists cannot.

Studies in Canada, Australia, and South Africa show that AI-driven exploration can:

- Reduce exploratory drilling by 20–40%

- Lower costs by millions of dollars per project

- Shorten timelines by months or years

Remote Sensing Enhanced by AI

AI-trained spectral models can identify alteration minerals associated with gold, lithological contacts, structural breaks, and soil anomalies. Drones equipped with hyper-spectral sensors now produce site maps with centimeter-level precision, allowing exploration teams to prioritize the highest-value drill targets. Before AI you couldn’t hit what you couldn’t see!

AI in Drilling and Extraction: Precision and Real-Time Optimization

Smart Drilling Systems

AI-enabled rigs adjust torque, rotation speed, and angle in real time based on rock hardness. This reduces equipment wear and improves penetration accuracy. Sensor arrays feed live data into machine-learning models that classify rock types instantly.

Also consider this: on-site AI analyzers evaluate ore quality without waiting for off-site labs. These systems can identify gold or silver grade, platinum-group concentrations, and the presence of impurities. This allows miners to instantly determine what should go to processing—improving profitability.

Autonomous Mining Equipment

These systems reduce accidents, operate around the clock, and enhance fuel efficiency. Major miners now use:

- Self-driving haul trucks

- Autonomous blast-hole drill rigs

- AI-guided loaders

- Smart conveyor systems

AI in Processing: Higher Recovery, Lower Costs, Smaller Footprint

Machine-Learning Process Control

AI continuously fine-tunes flotation chemistry, water usage, mill speed, and smelter temperatures. These optimizations typically increase recovery rates by 2–5%, generating millions in added annual revenue for mid-size precious-metal operations.

But that’s not all. AI can also predict energy demand and reduce consumption by 10–20%. Given that extraction consumes large quantities of energy, this is a meaningful efficiency gain. One more point, AI models also excel at identifying structural risks in tailings dams, detect seepage patterns, and monitor environmental indicators such as water quality and dust emissions.

4. Safety and Environmental Protection

Predictive Maintenance

AI forecasts equipment failures before they happen, preventing downtime and reducing catastrophic failures. Computer-vision systems identify workers near unsafe machinery, detect non-compliance with safety gear, and monitor underground instability.

Let’s not overlook the important improvements in environmental monitoring, including water contamination, air quality, noise levels, and habitat protection.

5. Sustainability: AI as the Engine of “Green Mining”

Perhaps at the top of the chart is precision mining. With AI, removing less rock, using fewer chemicals, reducing diesel combustion, and optimizing water recycling are all achievable. This is becoming a core requirement as governments and investors demand cleaner resource extraction.

6. Blockchain + AI: Transparent Precious-Metal Supply Chains

Now the blockchain part—and as fans of blockchain, I’m sure you already know that AI plus blockchain equals a tamper-proof digital record of:

- Mine origin

- Ore transport

- Refinery steps

- ESG compliance

- Responsible-sourcing certification

Smart Refining Contracts

Of course, the blockchain benefits don’t end there. They also include automated payments via smart contracts when AI-verified ore quality reaches contractual thresholds. And AI can scan blockchain records for fraudulent patterns. That’s gold-medal-winner level!

7. Limitations and Challenges

Of course, nothing is perfect. That’s why, when using AI in precious-metal exploration and extraction, users should be aware that large amounts of data are required to train the models, integration of sensors and AI equipment is costly, models need constant monitoring, and staff training needs its own budget line item.

Conclusion

The coronation of the new queen of precious metal discovery and extraction is complete. Wearing her artificial intelligence corona, she is reshaping precious-metal exploration and mining into a faster, safer, and more environmentally responsible industry. From her throne, her message is: as AI continues to merge with blockchain, sensor networks, and robotics, the mining sector is entering a historic transformation where data—not geology alone—will define future success.

Until next time,

Yogi Nelson

Sources & Citations

- McKinsey & Company – “The Role of Artificial Intelligence in Mining.”

- IBM Research – AI for Geoscience and Remote Sensing

- Deloitte – Tracking the Trends: The Top 10 Issues Transforming the Mining Industry

- Accenture – AI and Digital Twins in Mining

- Rio Tinto – Autonomous Mining Operations Reports

- World Gold Council – Responsible Gold Mining Principles

- Journal of Mining Science – Machine Learning Applications in Ore-Grade Prediction

- U.S. Geological Survey (USGS) – Mineral Resources and Remote-Sensing Studies

- MIT CSAIL – AI for Environmental Monitoring & Industrial Optimization